There is a manufacturer and a consumer, so the way a product reaches from the manufacturer to the end-user is very complex. It passes through various touchpoints. And the process work synchronously to maintain the flow. When this flow is not maintained, everyone in the chain will be affected adversely. As goods will reach the desired point so customers cannot buy the product. Eventually, when the product is not sold, revenue generation stops.

Page Contents

Definition of Marketing Logistics

Marketing logistics is about the flow of the actual products from a manufacturer to the consumer.

Prof. Philip Kotler defines logistics as “planning, implementing, and controlling the physical flows of materials and finished goods from point of origin to point of used to meet the customer’s need at a profit.”

The New Oxford American Dictionary defines logistics as “the detailed coordination of a complex operation involving many people, facilities, or supplies. “

What is Marketing Logistics?

Any company which is in the market and willing to offer the product efficiently (timely, cheaply) to the customers, needs good marketing logistics. We have manufacturers producing goods and retailers selling them to customers.

The set of activities that starts from the top (Manufacturer) to the bottom (end-user), is the first type, known as outbound logistics.

The second type is where logistics is working in the bottom to top direction, but this time from raw materials (Suppliers) to the manufacturing unit called inbound logistics.

There is also reverse logistics. When a customer is not satisfied with the product, a company can go the extra mile and would happily take the item back.

However, this dissatisfaction can arise because of various factors like issues with the size, color, quality, damaged item and so on.

So a reverse process will be activated where the company, at its own expense(most of the time) will arrange for a return of the item.

The item will be taken back from customers, then to the warehouse and finally reach the manufacturer.

Classification of activities

When we talk about logistics, it means transportation, inventory, and warehouse-related tasks, which are Primary activities.

Packaging, handling, scheduling falls under secondary activities under marketing logistics. But are equally important.

We can understand this way, a vase made of bone china will never reach its destination if not packaged properly.

Similarly, a perishable item will be handled completely differently. At times, the item is kept in cold storage and to take it from one point to another, a refrigerated van is required as well.

So, both types of activities work in tandem.

Primary logistics functions

Warehousing

The storage facility for a company. But why are they needed?

It is because, more often, there is a lag between the production and consumption cycle.

A very popular lawnmower company, Snapper, keeps their manufacturing unit up and running the entire year, and the company keeps on storing those finished products in the warehouses.

It is because when the demand peaks in spring, and they would be ready to meet them.

A company needs to decide how much is too much. Unsold inventory is again will cost the company dearly. So a data-based approach is best to adapt to understand the numbers.

Inventory management

Take the first scenario: a customer goes to buy a product but cannot buy it as it is out of stock, loss of revenue for the company and goodwill gets affected too.

In the second scenario, a company has unsold inventory, and the products are getting obsolete.

Which one is an unpleasant situation to have? Absolutely both.

Hence, a company has to decide based on market research how much to store in the inventory. And how much to produce at a point in time?

Another effective solution is JIT (Just in Time) technique.

In JIT, the company produces only a few items but will be on standby.

As soon as the products nearly run out, they resume production but again in smaller quantities and this cycle continues.

Here, “how much is too much?” or “how less is too less?” the quantity will be, should be researched at the granular level.

This study will be carried out before the start of the production season based on demand forecasting.

This provides ample time for the entire manufacturing process to run in harmony and never be in a crunch or in a hurry.

Transportation

Depending on the type of product and the reach, an appropriate mode of transportation is chosen.

As every mode has a different level of cost attached, which mode is suitable in which situation should be studied accordingly.

Trucks, railways, pipeline, air and water. These are the five modes to choose from:

Companies can also choose to have combinations wherever they feel necessary.

An important example is of gas or oil pipelines. PetroChina’s West-East Gas Pipeline covers 8,707km and is the world’s longest pipeline.

Without those immensely long pipelines, transportation of those items would have caused huge delays and the cost would have gone off the roof.

Logistics Information Management

At one retail location, there is a stock-out situation. The retailer has raised the request to refill the stock. But this information has not reached the manufacturer or reached after a long time because of the manual process. Quite possibly right?

Causing a big setback, be it monetary or goodwill.

A product goes through a chain of touchpoints to reach a customer. Communication is of uttermost importance.

But to have a seamless exchange of information, there is a need to set up a robust platform where anyone (Manufacturer, Supplier, Wholesaler, Retailer, etc) is aware of products in stock and the quantities associated.

EDI (Electronic Data Interchange) had been a very popular software to do this work. However, these days, we have quite a powerful software suite that excels in the said job known as, ERP (Enterprise, Resource Planning) making the entire process rather seamless.

Developing a logistics plan

Rather a critical process overall

Distance

When the distance increases, the cost and time get increased too. Whether a company willing to go distant places to deliver the product?

It is also required to understand customers’ willingness. Whether the customer will pay more for transportation or he/she is okay with the standard delivery model.

Speed of delivery

Who wouldn’t like a speedy delivery system? We are all aware of Amazon’s prime delivery. Similarly, as per the need, a customer would pay for the faster delivery. Once the need is identified, then the company can devise an appropriate mode of transportation and work out the associated cost.

Transportation modes

Depending upon the product, a mode is chosen. The modes as we are aware could be any of Air, Water or Road. It will also depend on the fact that where I would like to reach. Far-flung areas or only the urban region. Not always a single mode of transportation is workable, the company would then devise a combination that is cheaper yet delivers the product faster.

The goal of Marketing Logistics

We talk about maximum benefit with the least cost. However, to our surprise, logistics cannot work with this generic concept.

For example, suppose I have a manufacturing unit at location “X” and I will need to send the products to location “Y”.

So, what is a beneficial or cheaper way for me to do so, sending the products one by one or to send them in a bunch? The answer is obvious – in bunches.

But to get to the bunch, I will have to wait for all the items to be ready. The transportation will be on hold until then. The delivery period will increase for sure.

Now, what has happened at the other end?

The customer will be unhappy and dissatisfied because of the longer waiting period of the product he/she wanted to buy.

Practically speaking, it is like walking on a tight rope, extremely difficult to handle cost and time together.

Solution then?

The best approach is to set the delivery period according to the Target Customer service level.

Meaning, we will promise to deliver every single item the quickest.

But delivering product “A” in 2 days, product “B” in 5 days and so on. So that customers already will be aware and fine with the delivery timelines.

However, to conclude this is not that easy, what product will be delivered and in what time? A deep study is imperative to understand the importance of various distribution services, costs, and delays associated with them.

Developing flow of products

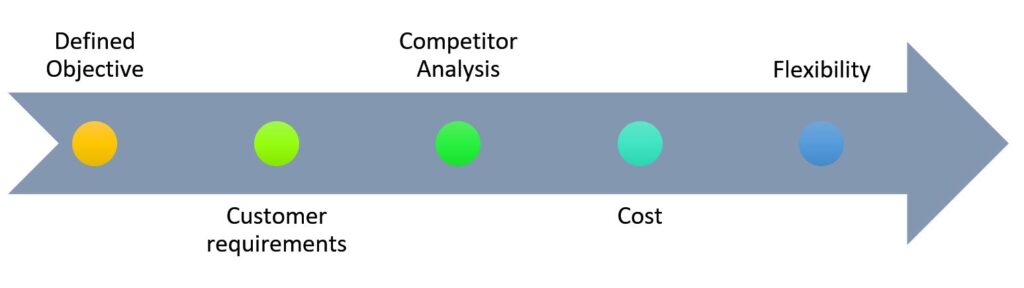

Step 1

Well-defined objective

Defining the objective, as well as related services, is certainly required in the distribution channel.

It means that it is critical to understand what kind of product I am dealing with. If it is a perishable item, then a different system will be required.

If I have electronic goods, then the requirement naturally will change, as they are fragile items.

Step 2

Customer requirements.

This is super important.

Without listening to the customer’s needs, no business will succeed.

For example, if I observe a customer has a low waiting appetite for a particular product and I am not prompt enough. Of course, the customer will turn towards a different product. FMCG products are of the same nature. A customer goes to buy a shampoo of his choice but there is no stock, he/she will not go on searching shop to shop, instead, he will buy which he feels next best option.

Step 3

Competitor analysis

Without comparing ourselves with a competitor, we wouldn’t know how well I am doing.

It is also important to understand how the competition is handling the distribution of the same or similar products which I am interested in.

When my competition is providing a product at $50 and I am selling at $70, definitely I will be out of the competition sooner than later.

Step 4

Cost

Business runs on profit. Minimizing distribution costs is one way of increasing the margins. However, the cost should not affect the quality of service I intend to offer.

Cost, if managed well, can provide a competitive advantage to the company.

Because no one will sell this cheap and still could make more profit.

However, if my service quality is top-notch, even if I sell the product at higher prices than others, still the customers will be more than happy to buy them.

Step 5

Flexibility

Today a company is delivering a product to the consumers. Tomorrow, the trend might change. Designing an entire system from scratch will have a catastrophic effect on the ongoing business.

Hence, the logistics chain should be such that some changes can be accommodated pretty easily without disturbing other components of the chain.

Conclusion

A robust chain and a flexible distribution system that is cost-effective and can deliver the products quickly are what any company dreams of.

Dreams can become reality if a lot of mind and heart go into designing and maintaining them well. It avoids stock-out and inventory costs at the same time.

Without an appropriate delivery system, a company cannot offer the products to the customer. But with a great system, a company will deliver the products in a cost-efficient way and still become a leader in the market.